© ROOT-NATION.com - Use of content is permitted with a backlink.

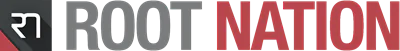

Chemists at MIT have developed a new type of photooxidation-reduction catalyst that can simplify the incorporation of light-controlled reactions into production processes. Unlike most existing photooxidation and reduction catalysts, the new class of materials is insoluble, so they can be used again and again. Such a catalyst could be used to coat the tubes and carry out chemical transformations of the reagents as they pass through the tube.

Chemical reactions that occur under the influence of light are a powerful tool for chemists who are developing new ways to produce pharmaceuticals and other useful compounds. Chemists have developed two main classes of photooxidation-reduction catalysts, which are known as homogeneous and heterogeneous catalysts. Homogeneous catalysts usually consist of organic dyes or light-absorbing metal complexes. These catalysts are easy to set up for a particular reaction, but their disadvantage is that they dissolve in the solution in which the reaction takes place. This means that they cannot be easily removed and reused. On the other hand, heterogeneous catalysts are solid minerals or crystalline materials that form layers or three-dimensional structures. These materials do not dissolve, so they can be used repeatedly. However, these catalysts are more difficult to adjust to achieve the desired reaction.

To combine the advantages of both these types of catalysts, the researchers decided to introduce dyes, which consist of homogeneous catalysts, in the solid polymer. This made it possible to reuse the catalyst repeatedly. The researchers found that the inclusion of catalysts in polymers also helped them become more efficient. That’s because the reagent molecules may be contained in the pores of the polymer, ready for the reaction. In addition, light energy can easily move within the polymer to find the expected reagents.

When applied to plastic tubes, catalysts can affect the chemicals that flow through them, helping to synthesize new drugs and other compounds. Researchers are currently working to incorporate a wider range of catalysts into their polymers and to develop polymers to optimize them for a wider range of applications.

You can also help Ukraine fight with Russian occupants via Savelife or via an official page of the National Bank of Ukraine.

Read also:

- The new 3D printing process is 30x faster than the traditional one

- Nuclear fusion can release more energy than previously thought